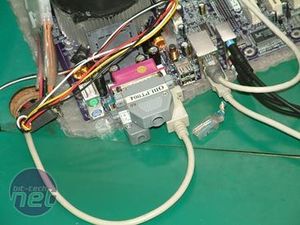

The interesting thing here is that every station has a different set of hardware. This allows ECS to test each production run with a wide range of components, without actually having to test every board with every configuration. This forms a part of ECS' compatibility testing, to ensure that its products work with components that its customers are likely to use with the board.

Finally, the boards are packed, ready for shipping. The boards that we have followed here are OEM motherboards and don't have retail packaging.

It was great to have the chance to go and see components manufactured right from the start, as it gave a whole new insight into the way that the industry works. The whole process is incredibly efficient considering the complexity of a motherboard in this day in age. We'd like to extend our thanks to ECS for giving us the chance to find out a bit more about how its company works. Unfortunately, we were not allowed to record any videos of the Rapid SMD Placement machines at work, because they were truely impressive.

So thanks very much to ECS for having us along!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.